At Ganpat Metal Steel Pipe/Tube/Tubing Quality Assurance

An ISO-certified company, Ganpat Metal is totally committed to follow innovative and most advanced quality testing procedures before dispatching any Pipes & Tubes from our Stockyard. we have fully automated equipped with latest testing Tools & equipment at our stockyard at Gujarat,INDIA.

Laboratory Testing

Ganpat Metal has fully equipped mechanical testing laboratory that perform the following tests:

Chemical composition with optical emission spectrometer:

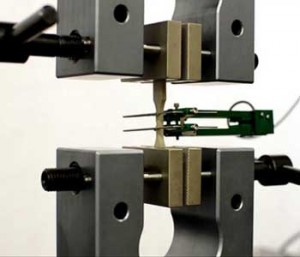

Tensile test for material yield strength, percent elongation, and weld tensile strength:

Notch impact test for percent shear area:

Notch impact test for energy absorption:

Microscopic test of weld cross section:

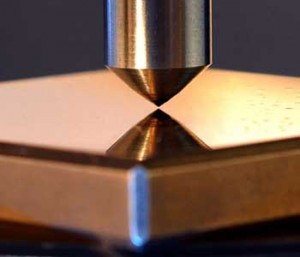

Hardness test:

Micro hardness test for hardness:

Drop weight tear test for percent shear area:

Guided bend test:

Flattening test:

Material Test Reports

At Ganpat Metal Pvt. Ltd., all test reports are computer-generated and available as per requirements of our clients we provide all test reports with shipment of our Steel Pipes & Tubes. also Reports are available of line pipe manufactured to API 5L specifications:

- Chemical analyses

- Mechanical property tests

- Fracture toughness tests

- Data regarding skelp properties

- Additional specific tests as requested by customer

Hydrotest

Line pipe is hydrotested to at least the API 5L specified minimum test pressure. we at Ganpat Metal ensure that Manufacturer of Line Pipe has provided pline pipe with hydrostatically test report as per to 100% specified minimum yield strength (SMYS). Pipe is tested with the weld line facing up, and the Specially trained & highly experienced HydroTest operator monitors the entire weld line during testing.

Ultrasonic Inspection

Ganpat Metal also provide primary nondestructive testing for quality assurance through the ultrasonic evaluation of the entire weld for each pipe & Tube.

Certified Training

Ganpat Metal is ISO certified for all quality Standards ASNT-TC-1A, Level III. our experienced experts who perform this testing are certified to ASNT-TC-1A, Level II.